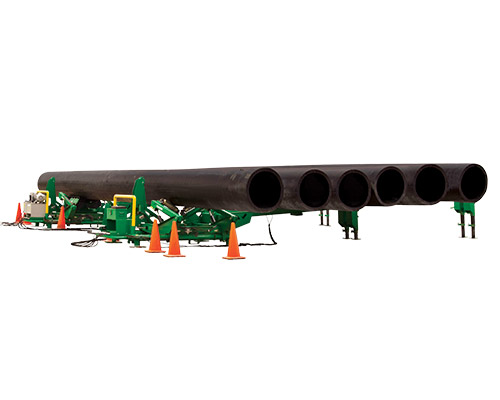

POLYHORSE

A new system to handle pipes that consists of a series of adjustable racks to store and help to install the pipes in the workplace. Among its advantages are to reduce labor costs, give an efficient environment and much less dangerous. You will increase productivity by 150%.

The operation consists in unloading the PE pipe of the delivery truck directly with the PolyHorse, where it is out of the way and out of the way until it is necessary. The operator rolls the tubing through the rack and onto the integral tubing rollers where it is easily loaded into a McElroy fusion machine. This eliminates the costs of additional lifting equipment and labor.

PARTS AND ACCESSORIES FOR THE POLYHORSE

Highlighted substitution parts and accessories

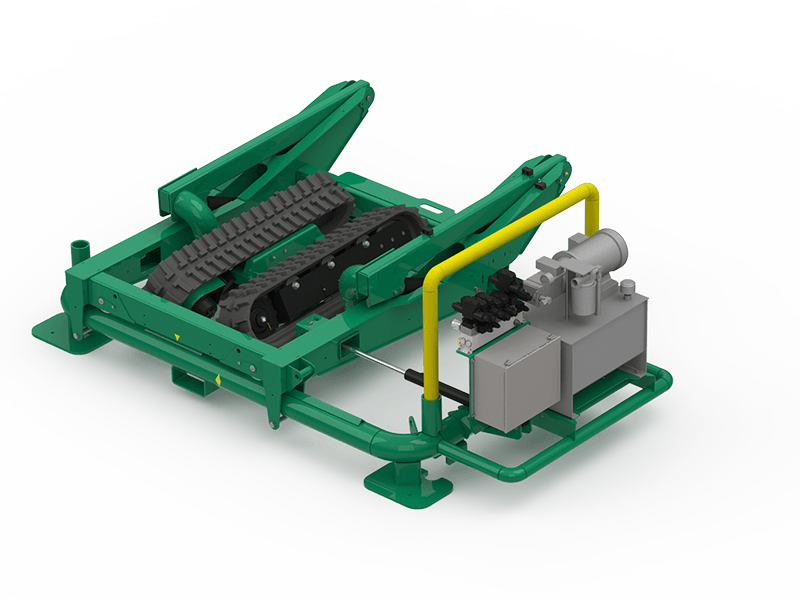

PowerAssist

Attaches to the closest truss to fusion operations and uses hydraulic power from the machine to effortlessly load pipe. For 3″ IPS – 20″ OD PolyHorse.

Stationary Roller

Attaches to the Screw Jack and supports the pipe for loading into the machine. For 3″ IPS – 20″ OD PolyHorse.

Pivot Roller Support

Attaches to the closest truss to fusion operations and lifts the end of the pipe above the height of the jaws to load pipe into the machine. For 3″ IPS – 20″ OD PolyHorse.

Screw Jack

Used to level the trusses. For 3″ IPS – 20″ OD PolyHorse.

Truss

Additional trusses for the 3″ IPS – 20″ OD PolyHorse. Standard truss. Compact truss

Stantion

Removable support to control pipe bundles. For 3″ IPS – 20″ OD PolyHorse.

SPECIFICATIONS

| PolyHorse® (traditional 3-truss setup) | MegaMc® PolyHorse® | |

| Maximum Load | 36,000 lbs (16,329.33 Kg) | 70,000 lbs (31,751 Kg) |

| Maximum Load Per Stick | N/A | 10,500 lbs (4,763 Kg) |

| PolyHorse® | MegaMc® PolyHorse® (240V) | MegaMc® PolyHorse® (415V) | |

| Input Voltage Requirements | N/A | 220V – 240V, 50/60Hz, 3Ph | 380V – 415V, 50Hz, 3Ph |

| Minimum Power Requirements | N/A | 5.1 kVA / 4.1 kW | 4.9 kVA / 4.1 kW |

INCREASE YOUR WORK EFFICIENCY REGARDLESS OF THE TUBE SIZES

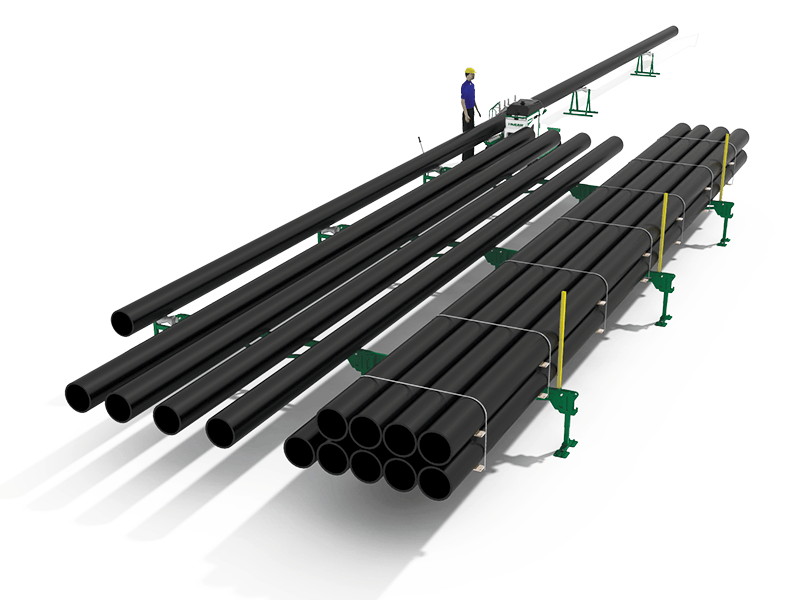

The Polyhorse is the most productive way to handle and store pipes of all kinds in the workplace. Get a safer work environment and reduce labor, expenses and time. The Polyhorse works through a series of adjustable frames available in two sizes: the standard PolyHorse®, for 3 «IPS to 20» OD (90 mm to 500 mm) or the MegaMc® PolyHorse®, for larger tubes from 20 «OD to 48» OD (500 mm to 1200 mm). They are designed to contain enough tubing for one day of fusion work and allow a single operator to load and align the tubing without the use of additional machinery. INCREASE YOUR WORK EFFICIENCY REGARDLESS OF THE TUBE SIZES

The Polyhorse is the most productive way to handle and store pipes of all kinds in the workplace. Get a safer work environment and reduce labor, expenses and time. The Polyhorse works through a series of adjustable frames available in two sizes: the standard PolyHorse®, for 3 «IPS to 20» OD (90 mm to 500 mm) or the MegaMc® PolyHorse®, for larger tubes from 20 «OD to 48» OD (500 mm to 1200 mm). They are designed to contain enough tubing for one day of fusion work and allow a single operator to load and align the tubing without the use of additional machinery.

SAVE IN TIME

AND IN WORKMANSHIP

MANIPULATE THE TUBES ONLY ONCE

At the moment the delivery truck appears with the tubes, these can be loaded directly onto the shelves of the Polyhorse. The system will take care of the pipeline from the delivery forward, eliminating the need for a piece of heavy equipment to tend constantly to the next length of the pipe. An operator can efficiently load and align each pipe bar in the fusion machine. The MegaMc PolyHorse includes remote control operations from the fusion machine.

POWER

YOUR TUBES

INCREASES PRODUCTIVITY THANKS TO ROLLERS ASSISTED BY ALL THE POWER

It diminishes the tension of the operator and the machine and increases the productivity with both of the models of our machines; The Polyhorse standard and the MegaMc PolyHorse. This machine can be purchased as a manual model or with our hydraulic PowerAssist system that will help you maneuver the tube up, down and inside the fusion car. Our other model, the MegaMc PolyHorse, has a pipe support with a motor and a caterpillar that is operated by remote control. This offers up to 24 inches of lateral movement and 34 inches of vertical movement to align the tube curved or outside the circumference.

SAVE

MONEY

We all know how valuable time is. Save on costs and get more productive. When organizing a full load of tubing in the racks of a PolyHorse, in one place, the costs of heavy machinery are drastically reduced. Instead of tying heavy equipment to meet the needs of the fusion machine, the PolyHorse allows the fusion machine operator to load and align the pipeline without assistance, decreasing the downtime and configuration time between each fusion.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| PolyHorse® | MegaMc® PolyHorse | |

| Modular design | ✓ | ✓ |

| Enhances productivity by up to 150% | ✓ | ✓ |

| Reduces job cost | ✓ | ✓ |

| Reduces manpower and additional equipment | ✓ | ✓ |

| Stationary rollers can double as a pipe stand | ✓ | ✓ |

| Quick setup | ✓ | ✓ |

| Multiple configurations depending upon your job | ✓ | ✓ |

| One operator can load, align and fuse pipe | ✓ | ✓ |

| Minimizes wear and tear on fusion machine | ✓ | ✓ |

| Easier to close jaws of fusion machine when properly aligned | ✓ | ✓ |

| No double handling of pipe, pipe moves from delivery truck to racks | ✓ | ✓ |

| Pipe stays cleaner off the ground | ✓ | ✓ |

| Adjustable height legs set rack incline and adapt to uneven terrain | ✓ | ✓ |

| Handles pipe sizes 3” through 20” (90mm – 500mm) | ✓ | |

| Maximum capacity of 70,000 lbs. (31,751 Kg) with a maximum pipe length weight of 10,500 lbs. (4,763 Kg). | ✓ | |

| 24” of lateral and 34” of vertical range of motion to align curved pipe with jaws of fusion machine | ✓ | |

| The productivity tool can be paired with any of McElroy’s MegaMc® line of fusion machines, as well as the TracStar® 500, 630 and 900 fusion machines. | ✓ | |

| Ships on one semi-trailer with fusion machine and generator. | ✓ |