DATALOGGER® 6

Guarantees 100% that the mergers of a board that you make in the workplace are always with the correct pressure and times according to the accepted standards. The enhanced tablet of the DataLogger 6 comes with an Android system that records and documents all the key parameters that are happening in the fusion process. This also covers the heat absorption times, the heating pressure, the opening / closing times, the melting time, the heating pressure, opening and closing times, melting time, melting pressure and resting time in cold. The operator will always have information in real time with graphics and information on the integrity of each merger board.

Stores and analyzes all the data collected with the DataLogger 6 in line with the DataLogger Vault. A software with which you can classify quickly and easily, labeling and exchange of joint records by machine, articulation, operator, device or work.

SPECIFICATIONS

| DataLogger® 6 | |

| Datalogging Standards | ASTM F3124 |

| Fusion Standards | ASTM F2620, ISO 21307:2011-05, GIS/PL2-3-07, Profuse, DS/INF 70-2 PE:HD:1992-05, WIS 4-32-08:2002-04, DVS 2207-1 PE-HD:2005-09, DVS 2207-11 PP:2008-08, DS/INF 70-2 PP:1992-05 |

| DataLogger® 6 | |

| Tablet | 1.77 lbs (0.8 Kg) |

| DataLogger® 6 | |

| Touch | Capacitive |

| Resolution | 1280 X 720 HD |

| DataLogger® 6 | |

| Operating System | Android 5.1 |

| Memory | 2Gb |

| Processor | Texas Instruments® OMAP 4430 Dual Core 1 GHz |

| Storage | 32GB |

| Battery | Lithium-Polymer 7600 mAh |

| DataLogger® 6 | |

| Wi-Fi | 802.11 abgn |

| Data | LTE & 3G/2G |

| Bluetooth | 4.0 |

| Location | GPS+GLNSS |

| DataLogger® 6 | |

| Front-Facing Camera | 2MP |

| Rear-Facing Camera | 8MP |

| DataLogger® 6 | |

| Barcode Scanner | 2D Scanner for pipe and fitting barcodes |

| DataLogger® 6 | |

| Barcode Scanner | Fully compatible |

DATALOGGER 6

ONE OF THE MOST VALUED TOOLS IN YOUR WORK

Those who build and manage pipeline infrastructures increasingly demand better record keeping. New standards, including ASTM F3124, have been implemented to regulate the collection of plastic pipe merger data. The Datalogger meets all market requirements by recording the most important information related to merger operations. Now it is easier than ever to add to better traceability and level of security before even starting to make the fusion of pipes.

COLLECT DATA DIRECTLY

The Datalogger 6 offers the necessary tools to collect the most important data during tube fusion. Scan the boat of your pipe or accessory to automatically enter the pipe material, size, date of manufacture and batch. You can also add information about the operator that operates the machine, work location by GPS, photos of welded pipes and much more.

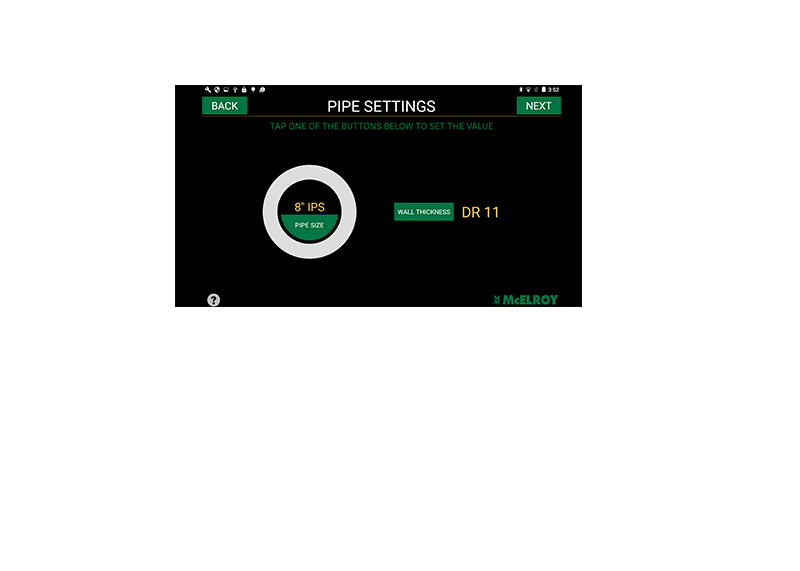

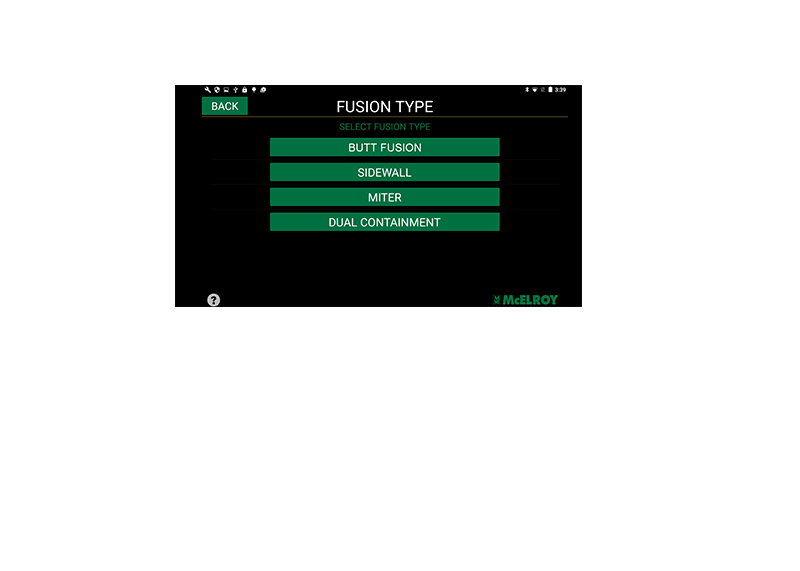

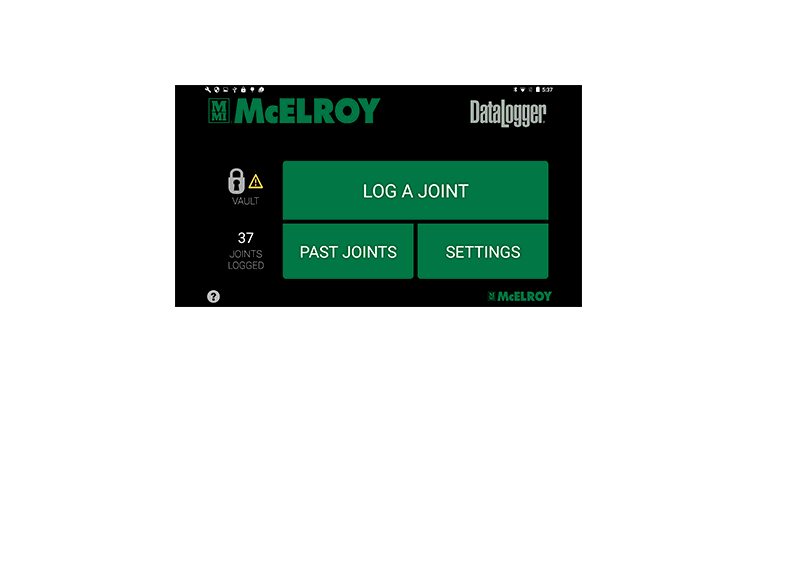

User-Friendly Interface

An entirely new interface was constructed from the ground up to be easy to use. Interaction studies and feedback from users in the field influenced the design for an intuitive and easy-to-understand new experience.

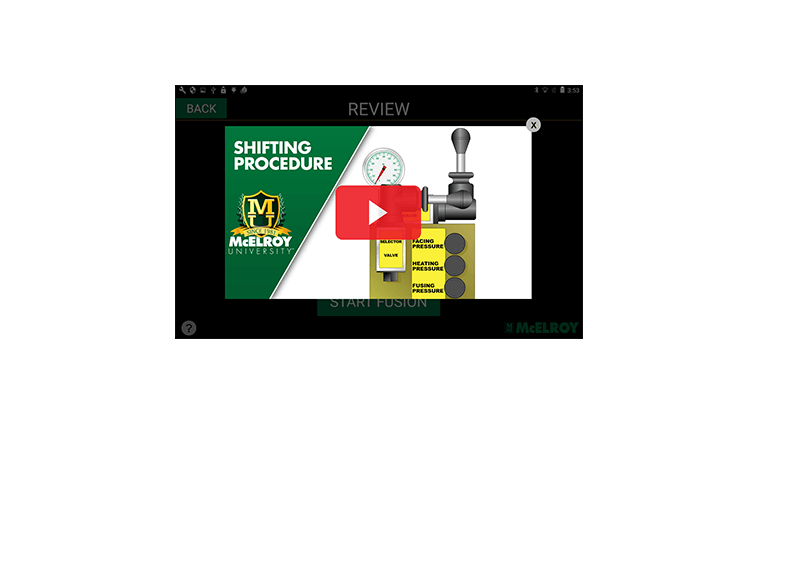

REAL-TIME ANALYSIS

MONITOR JOINT INTEGRITY DURING THE FUSION PROCESS

Use the machine to record and document all the parameters that happen during the fusion process. Always get fusions with the right pressure and times according to the accepted standards. The heat immersion times, the heating pressure, the opening / closing times, the melting time, the melting pressure and the cooling time are recorded. The real-time merge graph gives the operator immediate visual information and information about the integrity of each fusion merge.

COMPLIES WITH ASTM F3124 STANDARD

For the registration of merger data

Witht the Datalogger you will always be sure your workplace accomplishes with the latest standards, don’t take risks.

IP67 WATER AND RESISTANT POWDER

The DataLogger 6 resists every type of climate. Dust protection, wáter ressistant (1 meter deep). Capacitive touch screen friendly to gloves and uses a new technology called LumiBond to produce excellent visibillity even in direct sunlight.

CAPTURE GPS LOCATIONS

Register precise joint locations

Document the location where each board was merged. The precise GPS locations are saved with each joint record in your merge job.

WIRELESS SYNCHRONIZE

From the field or the office *

The joint records of the DataLogger can be stored and analyzed securely online in McElroy Vault ™, which allows a quick and easy classification, labeling and exchange of joint records by machine, articulation, operator, device or work. Use the built-in WiFi or a cellular signal to synchronize. When working in remote locations without a signal, the DataLogger 6 will synchronize joint reports as soon as a connection is established.

* Where the cellular signal is available

EASILY ENTRY SPECIFICATIONS

Improve efficiency in the field by scanning pipe and accessory information with the built-in 2D barcode scanner. Quickly document the characteristics of the fusion machine, operator information and more using the simple interface.

FRONT AND REAR CAMERAS

Capture job site conditions

Save photos of the conditions of the work and of each fusion union in each work. The DataLogger 6 is equipped with a front camera of 2 MP and rear camera of 8 MP that allows to capture and store photographs with data records of joint fusion.

SYNCHRONIZATIONS WITH MCELROY VAULT ™

Good information, together with an adequate analysis, is the key to a better understanding of your business. By collecting and analyzing data from your merger workplace, you can gain new insights into your general operations.

A simple in-field or off-site analysis can help ensure that each fusion joint was made using the proper procedures and meets industry standards. The data can improve the overall efficiency of the workplace and evaluate the productivity and individual performance of the operator. Joint Fusion records can also include GPS data to facilitate traceability.

Understanding and using the information obtained when logging into your merger activities can significantly improve your results. Finding new ways to manage, view and sort that data, and discover new metrics to follow will only improve your decision making and overall performance in the workplace. All this together adds real value for you and your customers.